When you think of an automatic transmission, you likely picture a complex system of interlocking gears that "shift" from one fixed ratio to another. But what if there was a transmission with no gears at all? This is the essence of the Continuously Variable Transmission, or CVT. Hailed for its exceptional smoothness and fuel efficiency, the CVT operates on a fundamentally different principle than traditional transmissions. This article is the first of a two-part series that will demystify the engineering behind this innovative technology.

The Core Components: Variators and the High-Strength Belt

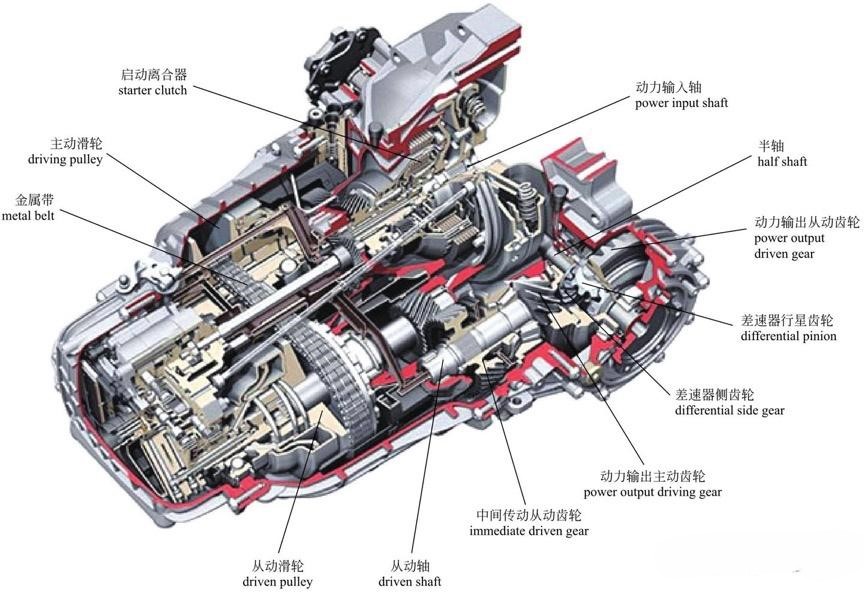

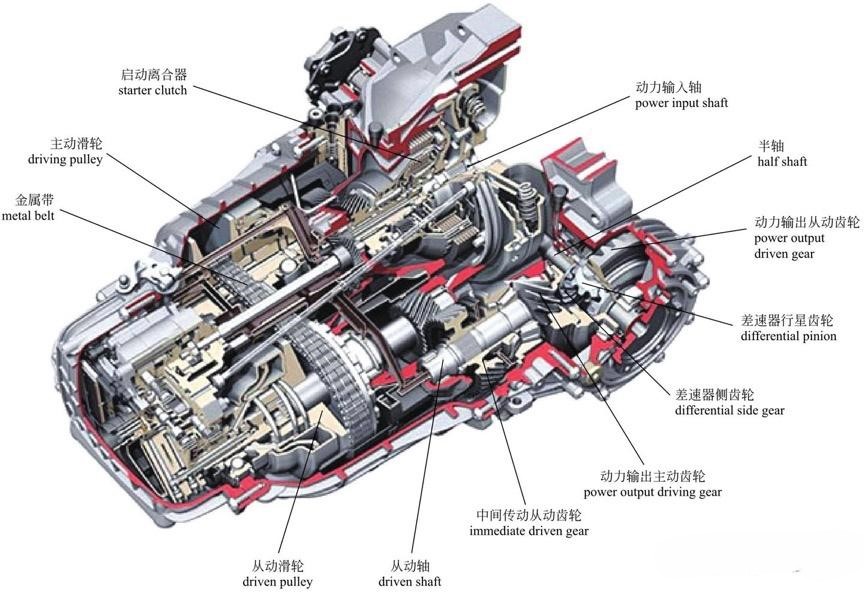

The magic of a CVT hinges on two brilliantly simple yet highly engineered components: the pulleys (or variators) and the belt.

- The Variators (Drive and Driven Pulleys): A CVT has two conical pulleys, each made of two opposing, 20-degree cones.

- The Drive Pulley (primary variator) is connected to the engine's crankshaft. It is the "input" side.

- The Driven Pulley (secondary variator) is connected to the wheels via the final drive. It is the "output" side.

- A key feature is that the sides of each pulley are not fixed; they can slide closer together or farther apart.

- The Steel Belt or Chain: This is the crucial link that transfers power between the pulleys. It's not a simple rubber V-belt. Modern automotive CVTs use a sophisticated, flexible steel belt composed of hundreds of thin, high-strength steel bands or plates held together by flexible steel rings. This complex construction allows it to handle immense tensile force while being flexible enough to bend around the pulleys. Some performance-oriented CVTs use a steel chain for higher torque capacity.

The CVT Principle: How "Infinitely Variable" Gearing Works

The genius of the CVT lies in the dynamic relationship between the movable pulleys and the steel belt. Here’s the step-by-step CVT principle in action:

- Low Gear / Acceleration (Low Ratio): When you press the accelerator from a stop, the transmission control unit (TCU) commands the drive pulley to widen. This forces the steel belt to ride lower in its groove. Simultaneously, the driven pulley is squeezed together, forcing the belt to ride higher. This creates a large "gear" on the input side and a small "gear" on the output side, equivalent to a low gear in a traditional transmission, providing strong initial acceleration.

- High Gear / Cruising (High Ratio): As the vehicle gains speed, the TCU orchestrates a seamless change. The drive pulley is slowly squeezed together, forcing the belt to ride higher up on its cones. At the exact same time, the driven pulley is allowed to widen, letting the belt ride lower. This reverses the effective "gear" sizes: a small input "gear" and a large output "gear." This is equivalent to a high overdrive gear, ideal for efficient cruising.

- The "Infinite" Ratios: Because the pulleys can move infinitely between their widest and narrowest points, the CVT can produce an infinite number of effective gear ratios. There are no fixed steps. This is the core of the continuously variable namesake.

Matching Engine Speed for Optimal Performance

The most significant advantage of this system is its ability to decouple engine speed (RPM) from vehicle speed. The Transmission Control Unit (TCU) is programmed to constantly adjust the pulley ratios to keep the engine operating in its most efficient or most powerful RPM band, depending on throttle input.

- For Maximum Fuel Economy: Under light throttle, the TCU will immediately adjust the ratio to bring the engine RPM down to its most efficient range (often around 1,500-2,000 RPM) and keep it there as the car accelerates. This avoids the RPM "sawtooth" pattern of traditional automatics that have to climb and fall through each gear. This is the primary reason people ask "is CVT fuel efficient?" and the answer is, in many driving conditions, yes.

- For Maximum Power (Wide Open Throttle): If you floor the accelerator, the TCU will set the ratio to keep the engine right at the peak of its power band (e.g., 5,500-6,000 RPM) and hold it there. The vehicle accelerates as the ratio changes, but the engine note remains a constant, high-pitched drone, which can be surprising to drivers accustomed to shifting gears.

In our next article, we will delve into the pros and cons of CVT transmissions, analyzing the trade-offs between their renowned smoothness and fuel economy and the common concerns regarding driving feel and long-term reliability.